To prevent a load from shifting, a comprehensive understanding of the causes, prevention techniques, consequences, and regulations is crucial. Load shifting poses significant risks to vehicle stability, safety, and the integrity of goods. This article delves into the intricacies of load shifting, empowering readers with the knowledge and strategies to mitigate its potentially catastrophic effects.

Uneven weight distribution, inadequate securement, and dynamic forces during transportation can contribute to load shifting. By employing tie-downs, straps, and other securement devices, ensuring proper load distribution and weight balancing, these risks can be effectively minimized.

Load Shifting Causes

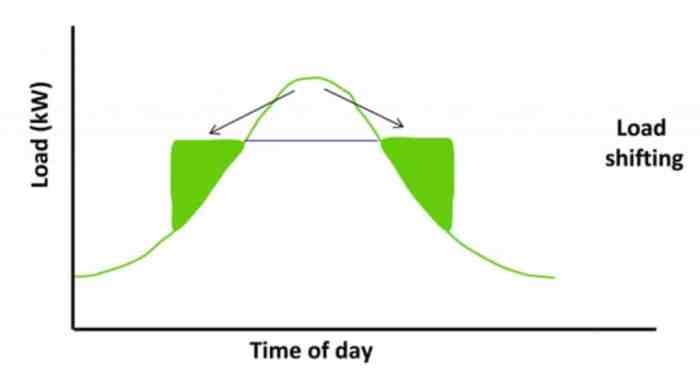

Load shifting refers to the movement of cargo or other heavy objects within a vehicle or container during transit. This can lead to a loss of stability and increase the risk of accidents.

Uneven Weight Distribution, To prevent a load from shifting

Uneven weight distribution is a major contributing factor to load shifting. When the weight of the cargo is not evenly distributed throughout the vehicle, it can create an imbalance that can cause the vehicle to shift or roll over.

For example, if a heavy load is placed on one side of a truck, it can cause the truck to lean to that side. This can make it difficult for the driver to control the vehicle and can increase the risk of a rollover accident.

Other Factors

In addition to uneven weight distribution, there are a number of other factors that can contribute to load shifting, including:

- Improperly secured cargo

- Sudden stops or turns

- Loose or worn-out suspension components

- Driving on uneven or slippery surfaces

Load Shifting Prevention Techniques: To Prevent A Load From Shifting

Load shifting is a common problem that can occur when transporting goods, resulting in damage to the load and potential safety hazards. To prevent load shifting, various techniques can be employed, ensuring the load remains secure and stable during transit.

One crucial method involves the use of tie-downs and straps. These devices help secure the load to the transporting vehicle, preventing it from moving or shifting during transportation. Tie-downs come in various types, including ratchet straps, cam buckle straps, and rope tie-downs, each suitable for specific load requirements.

Proper selection and usage of tie-downs are essential to ensure effective load restraint.

Another important aspect of load shifting prevention is proper load distribution and weight balancing. The load should be evenly distributed throughout the vehicle’s cargo area, avoiding concentrated weight in any one location. This helps prevent excessive stress on the vehicle’s structure and ensures stability during transportation.

Additional Securement Devices

In addition to tie-downs and straps, various other securement devices can be utilized to prevent load shifting. These include:

- Antiskid mats:Placed between the load and the vehicle’s surface, these mats increase friction, preventing the load from sliding.

- Edge protectors:Protect the edges of the load from damage and prevent shifting by providing a secure and stable base.

- Corner protectors:Similar to edge protectors, corner protectors safeguard the corners of the load, preventing damage and shifting.

- Dunnage bags:Inflatable bags that fill empty spaces within the cargo area, preventing the load from moving.

By utilizing a combination of tie-downs, straps, and other securement devices, along with proper load distribution and weight balancing, load shifting can be effectively prevented, ensuring the safe and secure transportation of goods.

Load Shifting Consequences

Load shifting, the movement of cargo within a vehicle during transit, poses significant risks and consequences that can impact vehicle stability, safety, and the integrity of goods or property.

Load shifting can occur due to various factors, such as improper loading techniques, sudden maneuvers, or changes in road conditions. Understanding the potential consequences is crucial for preventing accidents and minimizing damage.

Vehicle Stability and Safety

Load shifting can destabilize a vehicle, especially during turns, braking, or acceleration. When the load moves unexpectedly, it can alter the vehicle’s center of gravity, causing it to sway or lose control. This can lead to accidents, injuries to occupants, or damage to the vehicle.

Damage to Goods or Property

Shifting loads can also damage goods or property within the vehicle. As the load moves, it can collide with other objects, causing dents, scratches, or breakage. This can result in financial losses and delays in delivery.

In severe cases, load shifting can lead to catastrophic consequences, such as overturned vehicles or damaged infrastructure. Therefore, it is essential to take preventive measures to minimize the risks associated with load shifting.

Load Shifting Safety Regulations

To ensure the safety of personnel, equipment, and infrastructure, it is crucial to adhere to industry standards and regulations related to load shifting prevention. These regulations provide guidelines for the proper design, operation, and maintenance of equipment and systems involved in load handling and transportation.

Regulatory Bodies and Standards

- Occupational Safety and Health Administration (OSHA): OSHA sets standards for workplace safety, including regulations for the safe handling and transportation of loads.

- American National Standards Institute (ANSI): ANSI develops voluntary consensus standards for various industries, including load handling and transportation.

- International Organization for Standardization (ISO): ISO publishes international standards for a wide range of industries, including load handling and transportation.

Importance of Adherence

Adhering to load shifting safety regulations is paramount for several reasons:

- Worker Safety: Regulations help protect workers from injuries or fatalities caused by shifting loads.

- Equipment Protection: Proper load handling and transportation practices prevent damage to equipment and infrastructure.

- Legal Compliance: Failure to comply with safety regulations can result in fines, penalties, or legal liability.

Penalties for Non-Compliance

Non-compliance with load shifting safety regulations can result in significant penalties, including:

- Fines: Regulatory agencies may impose substantial fines for violations.

- Legal Liability: In the event of an accident or injury, non-compliance can increase legal liability.

- Loss of Certification: Non-compliance may lead to the suspension or revocation of operating licenses or certifications.

Load Shifting Case Studies

Load shifting incidents serve as valuable lessons for understanding the causes, consequences, and preventive measures associated with this phenomenon. By analyzing real-world cases, we can identify common patterns, contributing factors, and effective strategies for mitigating risks.

One notable case study involves a cargo ship that experienced severe load shifting during a transatlantic voyage. The incident occurred due to improper cargo stowage and inadequate securing measures. As the vessel encountered rough seas, the unsecured cargo shifted significantly, causing the ship to list dangerously.

The crew was forced to initiate emergency procedures to stabilize the vessel and prevent a potential capsize.

Another case study highlights the consequences of load shifting in the construction industry. During the erection of a high-rise building, a crane malfunctioned, causing a heavy load to swing and strike a nearby structure. The impact resulted in significant damage to the building and injuries to workers on site.

Investigation revealed that the crane had exceeded its rated capacity and the load was not properly secured.

These case studies underscore the importance of adhering to proper load handling and securing protocols. Failure to do so can lead to catastrophic consequences, including loss of life, property damage, and environmental harm.

Lessons Learned and Best Practices

- Proper cargo stowage and securing measures are crucial to prevent load shifting during transportation.

- Crane operators must adhere to rated capacities and follow safe operating procedures.

- Regular inspections and maintenance of load-handling equipment are essential to ensure reliability and prevent malfunctions.

- Adequate training and supervision of personnel involved in load handling operations are vital for safety.

Load Shifting Prevention Checklist

A comprehensive checklist is essential for preventing load shifting and ensuring the safety of transported loads. It provides a structured approach to identify and address potential risks, ensuring that all necessary precautions are taken.

The checklist should include the following key elements:

Load Inspection

- Verify the weight and dimensions of the load against the vehicle’s specifications.

- Inspect the load for any damage or instability that could compromise its integrity.

- Check for proper packaging and securement of the load items.

Securement Methods

- Select appropriate securement devices (e.g., straps, chains, ropes) based on the load’s weight and shape.

- Attach securement devices to strong points on the vehicle and the load.

- Tighten securement devices to the manufacturer’s specifications.

Weight Distribution

- Distribute the load evenly across the vehicle’s bed or trailer.

- Avoid placing heavy items at the rear of the vehicle, which can cause the vehicle to become unstable.

- Secure loose items or fill empty spaces to prevent shifting during transit.

By following this checklist, drivers and transportation professionals can significantly reduce the risk of load shifting and ensure the safe and secure transport of goods.

User Queries

What are the primary causes of load shifting?

Uneven weight distribution, inadequate securement, and dynamic forces during transportation are the primary causes of load shifting.

What are some effective load shifting prevention techniques?

Tie-downs, straps, and other securement devices, proper load distribution, and weight balancing are effective load shifting prevention techniques.

What are the potential consequences of load shifting?

Vehicle instability, compromised safety, and damage to goods are potential consequences of load shifting.